Pumps come in many different shapes and sizes depending on their desired use. When we look at commercial pumps used to move large volumes of water through outlets such as 100mm and 150mm pipes it should be expected that these fittings and pipes will experience some forms of vibration that can be detrimental to the overall system, it is with this vibration control should always be implemented.

Key Takeaways:

- What is vibration control

- What types of pumps experience high vibration

- Preventing a plumbing emergency

What Is Vibration Control?

Vibration control is the removal of shock or vibration from the infrastructure removing the liquid from the containment vessel.

At Mayfair Plumbing when we perform a new pump installation or a pump repair, we ensure the pipe work removing the liquid is bracketed at close intervals and the brackets themselves have rubber between the pipe and the bracket to eliminate any shock waves running through the pipes each time the pump starts up.

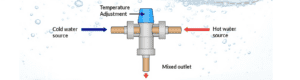

Between the pump and the pumped discharge line it is also important to install a vibration control boot. This piece of equipment is a rubber boot which bolts onto the pump and onto the pumping drain. The vibration boot is pressure rated to PN16 (1600kpa) and takes the initial start-up and shut off shock away from the ridged pumping line.

You will also see these anti vibration boots used in pressure and circulating pumps which move potable hot and cold water around buildings. Given the constant running of these pumps there is a gentler vibrant, but constant and this can cause items such as nuts and bolts on the table D and table E flanges to vibrate loose if not installed by a licensed pump technician.

What Types Of Pumps Experience High Vibration?

All pumps will experience some form of vibration either during start up or shut down or even during there normal running cycle. If we consider what pumps experience the largest amount of vibration, then it is mostly submersible pumps, storm water pumps and submersible grinding/cutting/macerating pumps.

Large commercial submersible pumps used in the transfer of storm water and sewer at high volumes will have a huge amount of torque behind them and when they start up and begin to transfer the liquid the pump will create a significant surge. If the pipe work is not correctly bracketed and the correct vibration control implemented, it will lead to cracking and shearing off various parts and fittings involved with the pump’s installation.

Pumps which are used in commercial and industrial applications have outlet sizes of between 80mm through to 150mm and over. Given the size of their outlets the volume of liquid being processed is huge. Brands you will hear commonly installed are Grundfos, Franklin, Lowara, Pedrollo, Davey, Flygt and Sistema. These pumps are often over 100 kilograms in weight and not the type of thing you want to be moving around regularly. It is important to plan the location of the pump and secure all parts to enable text book operation and avoid unnecessary strain on the pipe’s connections.

How To Avoid A Plumbing Emergency With Pumps

At Mayfair Plumbing we handle majority of the commercial pump sector in Adelaide and across the state of South Australia including the Adelaide Hills and Fleurieu Peninsula. We provide an on call 24-hour service for when a pump emergency does occur

What we also provide is scheduled maintenance for all our domestic and commercial customers. A pump which removes sewer or storm water in a large capacity for an apartment block, hotel, housing estate, factory, and hospitals etc we recommend quarterly inspections to minimise down time and avoid an emergency plumbing call out to fix preventable pump repairs.

FAQ’s

Where do I get spare parts for a pump?

At Mayfair Plumbing we carry majority of the common spare parts to fix a pump on the spot. Items such as failed swing check non return valves, split hoses, broken cam lock fittings and faulty float switches are all common problems which we carry as spare parts to get your pump up and running again quickly.

What can be done if a pump breaks down?

When a pump breaks down in a commercial or industrial application it will set off a flashing light and sometimes emit a noise to alert people of the error state. In majority of cases a commercial pumping station will have dual pumps installed. The idea behind dual pumps is to ensure that is one pump was to fail the other would take up the load until such time as the liquid level drops or the second pump was fixed or replaced.

What warranty does a commercial pumping system come with?

Each manufacturer is different with their warranty periods on large pumps. What we find is that with Grundfos they offer a 2-year warranty. Some manufacturers will offer a 3-year warranty and others offer 1 year. It is important to always follow the manufacturers guide lines and always use a licensed plumber and electrician where required.