How does a Centrifugal Pump work?

A centrifugal pump works by converting motor energy into kinetic energy. This energy pushes fluid out from the centre of a spinning impeller to the edge of the pump and then out of the pump at the outlet due to the increased velocity and pressure, producing a steady pressure.

A centrifugal pump uses the energy from an engine or electric motor to increase fluid pressure and move liquids through a system. This type of pump is known for its simplicity and efficiency, converts mechanical energy into kinetic energy, for fluid flow in applications like water supply, air conditioning and industrial pumping. Here we will go through each component that makes a centrifugal pump work.

What is a Centrifugal Pump?

A centrifugal pump is a hydraulic device that converts mechanical energy into hydraulic energy by centrifugal force applied to the fluid. It works by rotating a component to give velocity to the liquid which is then converted into flow. The operation of a centrifugal pump relies on many mechanical components to work together, the pump shaft, bearings, sealing system, structural components and wear surfaces.

Centrifugal Pump Market Statistics

Below are the market statistics for centrifugal pump market worldwide.

Market Size and Growth

Global Market Value: The global centrifugal pump market was USD 33.69 billion in 2023 and is expected to reach USD 59.95 billion by 2032, at a compound annual growth rate (CAGR) of 6.76% during this period.

Regional Insights:

Asia-Pacific has the largest market share, USD 13.45 billion in 2023. This is driven by increasing energy demand and growth of manufacturing industries.

In the US, the centrifugal pump market is expected to be USD 5.99 billion by 2032, due to construction and infrastructure development projects

Applications of Centrifugal Pumps and Industries

Water Supply and Wastewater Management: Centrifugal pumps have many applications, across industrial, agricultural and domestic sectors. These pumps are used to transport clean water and manage sewage systems.

Agriculture: They are used in irrigation systems.

Industrial Manufacturing: Used in chemical processing, food production and power generation.

Construction and Infrastructure: Increased construction activities due to urbanization is driving demand for these pumps in residential and commercial buildings.

Energy Consumption

Centrifugal pumps account for about 12% of total industrial electricity use in Australia, that’s how much energy they consume in industrial applications.

This means energy efficient design and operation to reduce the cost of electricity consumption.

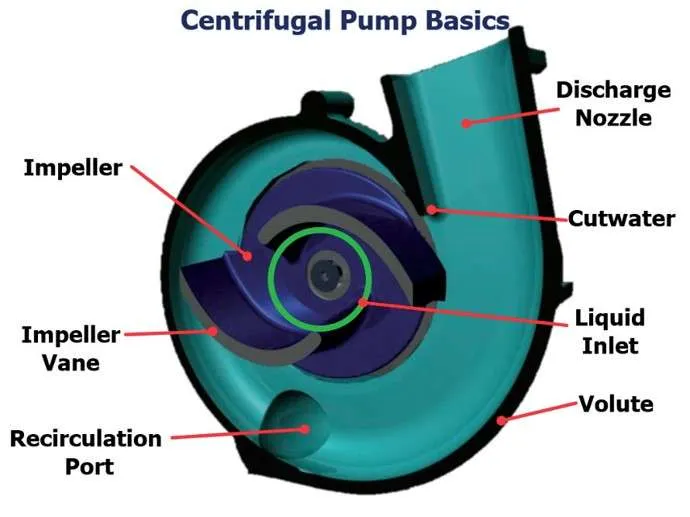

Components of a Centrifugal Pump

A centrifugal pump has the following components that makes it work efficiently. The pump casing is the one that converts the kinetic energy from the impeller into pressure energy so fluid can move efficiently. These are the pump impeller, volute casing, mechanical seals and pump shaft.

Components Explained:

Impeller: The heart of the pump, the centrifugal pump impeller spins fast to create centrifugal force.

Volute casing: This spiral casing converts kinetic energy from the impeller to pressure.

Mechanical seals: These prevent fluid leaks around the pump shaft.

Pump shaft: Connects the impeller to the motor and rotates.

Foot valve: Used in self-priming pumps to prevent backflow.

Fluid Flow

In a centrifugal pump, fluid enters the suction line and flows to the impeller’s eye. The impeller rotates fast and pushes the fluid to the edges, increasing both kinetic energy and fluid pressure.

Fluid Flow Steps:

Fluid enters at the impeller’s eye.

Rotational energy from the motor spins the impeller.

Fluid pressure increases as fluid moves to the volute casing.

Types of Centrifugal Pumps

Centrifugal pumps come in different designs to suit specific fluid and pressure requirements. Common types are radial centrifugal pumps, self-priming centrifugal pumps and submersible pumps.

Centrifugal Pump Types:

Radial pumps: Creates high pressure by moving fluid perpendicular.

Self-priming pumps: Handles air and low viscosity fluids without manual priming.

Submersible pumps: Operates underwater, suitable for high viscosity fluids and sewage applications.

Energy Conversion

A centrifugal pump’s impeller converts mechanical energy from the motor to hydrodynamic energy in the fluid. The rotational kinetic energy gives velocity to the fluid and then converts to pressure energy in the volute.

Conversion:

Mechanical energy from the motor spins the impeller.

Fluid gains kinetic energy as it passes through the impeller.

Kinetic energy converts to pressure energy in the volute casing.

vs Positive Displacement Pumps

Centrifugal pumps work differently from positive displacement pumps. Positive displacement pumps move fluid by closing a fixed volume and mechanically moving it through the system while centrifugal pumps use centrifugal force to accelerate fluid and increase pressure.

Centrifugal pumps are generally good for high flow low pressure applications while positive displacement pumps are good for low flow high pressure applications.

Advantages and Disadvantages of Centrifugal Pumps

Advantages:

Efficiency: Good for low to medium viscosity fluids and high volume transfer.

Simple design: Few moving parts means less maintenance.

Versatility: Suitable for various fluids from water to chemicals.

Limitations:

Pressure Drops: Efficiency decreases with changing pressure conditions.

Shear Sensitivity: Not suitable for shear sensitive fluids or high viscosity materials.

Priming Requirement: Many centrifugal pumps require priming unless self-priming.

Maintenance and Troubleshooting of Centrifugal Pumps

Regular maintenance is necessary to ensure centrifugal pumps perform optimally and last long. This includes regularly inspecting the pump and its components, cleaning the pump and its components, lubricating the moving parts, replacing worn out parts and performing routine maintenance as recommended by the manufacturer.

Common issues with centrifugal pumps are cavitation, vibration and overheating which can be caused by misalignment, imbalance or worn out bearings.

Troubleshooting these issues requires understanding of the pump’s operation and components.

Common Questions

Below are some of the FAQs we get.

How does the design of a centrifugal pump affect its efficiency?

The design of a centrifugal pump plays a big role in its efficiency. Impeller shape, size and material affects how well the pump converts mechanical energy to hydraulic energy.

A well designed impeller minimizes turbulence and maximizes flow which reduces energy losses. And the pump’s operating point relative to its Best Efficiency Point (BEP) is critical; operating away from this point will increase energy consumption and wear.

What is the role of fluid viscosity in centrifugal pumps?

Fluid viscosity is a key factor in selecting a centrifugal pump because it affects the pump’s performance and efficiency. Centrifugal pumps are generally good for low viscosity fluids, high viscosity will increase resistance and reduce flow rate.

If the fluid’s viscosity exceeds certain limits it may require a different type of pump like positive displacement pump to maintain efficiency and prevent power consumption.

Can centrifugal pumps handle solid laden fluids?

While centrifugal pumps are designed for liquids, they can handle some solid laden fluids if specific design considerations are made. Pumps with open or semi-open impellers can handle slurries or fluids with small solids.

But using centrifugal pumps for highly viscous or abrasive materials will cause rapid wear and damage. You should assess the type and concentration of solids in the fluid before choosing a centrifugal pump.

What happens when cavitation occurs in centrifugal pumps?

Cavitation occurs when the pressure in a centrifugal pump drops below the vapor pressure of the fluid and vapor bubbles form and collapse violently.

This can cause damage to the impeller and other components and reduce performance and costly repairs. To prevent cavitation ensure proper installation, maintain sufficient suction pressure and avoid operating the pump at low flow rates that can cause pressure drops.