We have recently been engaged by a client in Millswood to investigate a bore pump that is not working correctly. The bore is used to irrigate their property which is set on 3,000 square metres of beautifully manicured plants and gardens, so the importanance of this key piece of infrastructure working is crucial to keep the property in pristine conditions, especially during the warmer months of the year where we have had very little rain so far in 2022.

Problems With The Bore

On our first visit we found that the bore had an air lock and once purged from the line the pump started and could not be faulted. Two weeks later the client contacted us to say that the bore had completely stopped working and they wanted us to re attend and perform further investigations and a report etc.

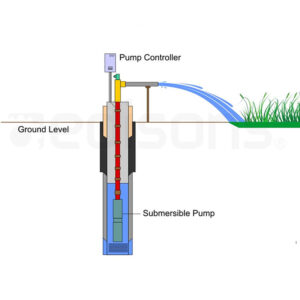

We attend the site and proceed to raise the bore from below ground, luckily this bore was only 19 metres deep and was installed on a 32mm blue line pipe system which made raising the bore pump relatively easy with two people. Once we had the pump out of the ground, we could inspect the pump and the non-return valve. We removed the 32mm non-return valve to find that this had 100% failed and needed replacing. When the non-return valve is failing it will cause the pump to lose its prime and make starting the pump very hard.

We replaced the non-return valve and connected it back to the stainless steel Grundfos submersible torpedo pump. The bore was then carefully lowered back into its hole. We then proceeded to fill the 32mm blue line bore pump line with water to confirm that the new non-return valve was sealing and perform its correct task, which it was.

Testing The Pressure Control Module

Once the bore was back into the well, we could then start to test the pressure control module and see if this was also causing any issues relating to faults with this set up? When the power was turned onto the pressure controller, we could hear the pump turning on, yet no water was coming from the pump itself? This would indicate that the pressure controller was also playing up. As it turns out that current pressure controller was only rated to 8amps, yet the pump is delivering nearly 9amps, so this arrangement has never been correct since it was initially installed 14 years ago. We explained the results from our inspections to the customer and then proceeded to quote the additional works moving forward.

Once the quote was accepted, we ordered the new Kelco F60 MK3 Intelligent Pump Controller from our preferred electrical wholesaler Rexel in Mount Barker. The new control module had to come from NSW as stock levels have been depleted throughout the covid pandemic in Adelaide. The controller took a couple of days to arrive, and we managed to get back to the client’s house before the Easter long weekend.

Installing The Kelco f60 MK3

The installation of the Kelco F60 MK3 Intelligent Pump Controller requires a licensed plumber and electrician to perform the correct installation. The pump controller has a paddle at the bottom of the unit which is used as a flow switch so that the moment water moves through it is detected and activates and then starts to perform its job. The paddle comes from the factory to accommodate pipe sizes from 25mm up to 100mm, the plastic paddle is cut to the size required ranging from small diameter bores of 25mm up to larger delivery pipes of 100mm.

What we like about the Kelco Pump Controllers:

- The controller will detect if there is water coming up from the well below and turn the pump off if there is no water detected, it will then try again after a set amount of time. The design of this is that it will protect the pump from burning out due to a dry well. This is also a key feature required by many home insurance policies as it will state in the fine print that if a bore does not have run dry protection the policy may not cover the bore pump, this would also be the same for the pumps warranty policy as well.

- Pressure display is digitally shown on the front page of the LED Control panel showing start pressures and delivery pressures. In this case the Grundfos pump delivers 600kpa of pressure when working at full speed.

- Flow rates are digitally displayed giving an accurate reading of what amount of water has been delivered from the bore.

- Burst pipe detection adjustable from 1 minute to 99 hours and 59 minutes adjustable in 1-minute increments, when used in the mode 3.

- 15 Programmable options are designed to suit numerous applications. The Intelligent controller can be setup to fill storage tanks daily, it can also be programmed to turn off in the event of no water and try again the next day. This controller can also be used on low voltage electricity with the F60-12-Mk3 model as well as mains 240 volts and 3 phrase power supply with the F60 Mk3 version (used in this project at Millswood, single phase supply).

- Dedicated alarm relay.

- Detachable electrical housing for safe inspections and maintenance.

- Blue tooth capabilities. Like many devices today the Kelco controller can also be equipped with a blue tooth controller as an additional purchase.

- Waterproof IP64 rated casing means the controller can sit outside exposed to the elements while still be 100% active and not be affected by the rain or sun year-round.

- Ambient temperature ranges from 1 degree Celsius to 50 degrees Celsius. Liquid temperature ranges from 1 degree Celsius to 60 degrees Celsius.

- Established in 1974 and operates from Brookvale in Sydney, NSW, Australia.

Advantages Of These Pump Controllers

The advantage of using these new intelligent controllers is that it takes away the need for bulky switch boards with outdated manually operated devices with multiple sensors/floats and allows for a smarter/neater installation with a huge amount of new technology compactly installed. The Kelco F60 MK3 is a very compact unit and holds a heap of options to suit almost any bore pump type arrangement and can be installed in some of the tightest bore pits across Adelaide and the Adelaide Hills of South Australia.

At Mayfair Plumbing we are one of only a handful of hydraulic services companies to have a dedicated pump division continually up skilling/training and evolving with new technology such as the Kelco F60 Mk3, IPG20 Mk3, F29 Mk3 and E30-Mk2 to ensure our clients are kept up to date with all the latest technology helping them get the best out of the bore pump installations across Adelaide and the Adelaide Hills of South Australia.

Our company has a current public liability insurance certificate, all our pump technicians hold current white card safety clearances and we provide a comprehensive SWMS along with all MSDS required for each site as required.