Throughout South Australia majority of large ground spaces which take vehicular traffic from cars, trucks, aeroplanes, trains and the likes will have some form of Gross Pollutant Trap installed and in the case of an airport or shipping yard multiple treatment stations will be used to ensure the large volumes of water are captured for pre-treatment.

What Is A Gross Pollutant Trap?

The role of a Gross Pollutant Trap is to stop large debris, silt and contaminated liquids from entering the storm water system and making its way out to the ocean. There are many different models on the market today and each perform this task in different ways depending on the loads placed on them.

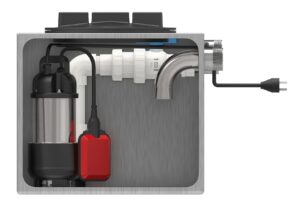

Some of the more basic Gross Pollutant Traps installed where demand is anticipated to be low there will be for example a small pit approx. 600mm Square with a grated inlet and anywhere up to 3 metres in depth. These systems produced by Fox Environmental Systems in Australia rely upon a settlement process in which any debris will gradually drop to the base of the pit.

The outlet to the street table or onsite pumping station is positioned in such a way that the pit will always hold water to enable the contaminants to stay onsite. This particular product has two sizes for its outlet either 150mm or 225mm. At regular frequencies companies such as ours come and perform programmed maintenance and keep the storm water infrastructure working.

In more complex high demanding scenarios such as an Airport or even a Petroleum holding facility SPEL Stormceptors are used. These can be up to 12 metres in length and be installed up to 10 metres below ground depending on the surrounding infrastructure. These types of Gross Pollutant Trap may be used to treat the storm water from an entire suburb prior to transfer via a large pumping system out to the ocean. These types of systems rely upon a more complex process of handling the waste.

In the first chamber heavy particles which first enter will settle to the bottom such as silt and other granular deposits and plastic etc which float will also stay there for future collection.

The second chamber will allow liquids such as fuel and oil to rise to the surface for future collection. When the Stormceptors has reached its capacity, the alarm will recognise a high level of hydrocarbons and a flashing beacon will emit alerting the property users that vacuuming of the first chambers silt sediment and floating debris need removing and skimming of the second chamber contents to remove oils etc. You can see a detailed explanation of this in the video on this page.

Trap Maintenance Is Important

Like most plumbing fixtures they need regular maintenance in order to ensure they continue to work as per the manufacturers intended specifications. The role on effects of a Gross Pollutant Trap not being maintained can be as follows:

- Major blockages in the storm water infrastructure causing catastrophic flooding.

- Vehicular damage and crashes.

- Pump failure due to large particles and dirty liquids making their way into impeller and causing the pump to overheat and burn out the motor.

- Extensive vacuuming of Gross Pollutant Traps.

- Hydro Jetting and CCTV Camera investigations to remove stubborn blockages.

- Excavation of Gross Pollutant Traps to repair damaged sections.

Inspection Tasks

Depending on the location of your Gross Pollutant Trap and its surrounding environments will determine how frequent you should have the device inspected and cleaned. In environments with high traffic volumes, large spill ratios and large vegetation with heavy foliage we may suggest quarterly maintenance periods or more regular depending on the amount of debris being removed. During a standard inspection we will perform the below tasks:

- Traffic control and make safe of the area to be worked on.

- Removal of Gatic lids.

- Removal and cleaning of any pre catchment filters which will filter out large items such as cans, bottles and other large objects.

- Vacuuming and disposing of all sludge and decomposing matter to EPA guidelines.

- Testing operation of pumping systems.

- Cleaning out of pumps if required.

- Testing of all pump float switches including high level alarm modules.

- Commissioning of Gross Pollutant Traps once cleaned.

- Reinstatement of Gatic lids.

Environmental Considerations

With a continual growing concern for the environment Gross Pollutant Traps are becoming far more popular. Their design is becoming more complex. Gross Pollutant Traps are today being engineered to allow greater volumes of water through at faster rates to allow higher volumes to be treated ensuring the storm water is removed off site as fast as possible while also treating the water at higher efficiencies.

The Stormceptor as touched on earlier has been engineered to remove up to 95% of silt from the water it treats, it also delivers water quality at 7.5% better than the current EPA water quality guidelines.

As the water quality that exits these treatment stations increases so has the onsite use of the water. The treated rainwater can be pumped into above ground holding tanks or transferred via gravity into underground storage tanks. Many commercial and industrial facilities today will use the storm water for flushing toilets and urinals. Properties with large areas of vegetation will use this watering. If the infrastructure is correctly set up from the initial build stage the advantages are significant for cost saving during a facilities operation.

At Mayfair Plumbing we have over 20 years of experience across Adelaide and in the Adelaide Hills of South Australia with installing various Gross Pollutant Traps and maintaining these systems many years after they have been installed. Some projects involve large 30 tone excavators and dump trucks to enable huge holes to be excavated and then 100 tone cranes to lift these systems into the holes.

Our team is skilled to handle all aspects of a new installation and all future maintenance work. We work across the whole state of South Australia including remote locations. All staff members hold current White Cards and tasks specific Safe Work Method Statements (SWMS).